Powder Coating Procedure:

- Processes to be completed are identified and a work order is created tailored to the processes to be completed.

- Most products go through a three stage Iron Phosphate was system and is cleaned at 180 degrees’.

- Masking and plugging of hardware per customer drawing’s is next.

- Proper powder coating is selected and applied to proper thickness.

- Parts are then baked at powder mfg specifications. Generally around 400 degrees F.

- Parts are inspected and de-Masked.

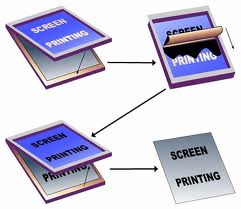

- Silk Screened if needed per customer drawings.

- Final Inspection and packed for shipping by best method or customer instructions.

Powder Coating Capabilities:

- Hundreds of stock colors and textures available. Custom colors and color matching available.

- Masking to your drawings specifications. On-site silk screening and many colors.

- Prototype to production runs. Masking of all hardware available prior to finishing.

Powder Coating and Silk-Screening Over These Materials:

- Cold rolled steel, galvanized steel, and aluminum.

- Silk-Screening on all of the above including powder coating, Zinc plating, Anodized Aluminum and plastics.

Phosphate Wash System